In the dynamic landscape of warehousing and logistics, efficiency is paramount for businesses seeking to streamline operations and reduce costs. One innovative solution that has gained traction in recent years is the use of slip sheets. These thin sheets, typically made from cardboard or plastic, offer a lightweight alternative to traditional pallets, enabling companies to maximize space, enhance load stability, and improve environmental sustainability.

As warehouses strive to optimize their storage capabilities, slip sheets prove to be a versatile asset. By allowing for more compact stacking of goods and reducing the overall weight of shipments, slip sheets can transform how products are handled and transported within a facility. This introduction of slip sheets into the supply chain not only boosts operational productivity but also minimizes material waste and lowers transportation expenses.

In this article, we will explore the various slip sheet solutions available and how they can significantly enhance warehouse efficiency. From understanding the key benefits of adopting slip sheets to examining best practices for implementation, we aim to provide insights that can help businesses harness the power of this emerging tool in the logistics industry.

Slip sheets are flat sheets made from material such as cardboard or plastic that serve as a durable alternative to pallets in warehouse operations. They are designed to facilitate the movement and storage of goods, especially in environments where maximizing space and improving efficiency are critical. According to a report by the Material Handling Industry of America, the use of slip sheets can reduce material handling costs by up to 25%, making them an attractive option for many warehouses aiming to optimize their operations.

A notable advantage of slip sheets is their ability to enhance space utilization. Unlike traditional pallets, which take up additional vertical space, slip sheets can be stacked closely to maximize storage density. This contributes to more efficient warehouse layouts and reduces the overall footprint required for inventory. Furthermore, slip sheets can operate effectively with special handling equipment, such as slip sheet attachment trucks, which are often more economical and require less maintenance than traditional forklifts.

Tips: When integrating slip sheets into your warehouse, ensure that your staff is properly trained in their usage to avoid handling issues. Additionally, consider conducting an analysis on your current space utilization, as this can highlight the potential benefits and cost savings of transitioning to slip sheets. Regular maintenance of the equipment used with slip sheets is also crucial to ensuring safety and efficiency in your operations.

Slip sheets have become an essential tool in optimizing warehouse efficiency, offering a versatile solution for various types of warehousing needs. These flat sheets, typically made from materials such as paper or plastic, enable easier handling and transport of goods. There are several types of slip sheets available, each tailored to specific warehousing requirements.

For instance, heavy-duty slip sheets are ideal for bulkier items, allowing for increased load stability during transportation. In contrast, lightweight options may be more suitable for smaller, lighter products that require frequent handling.

The benefits of using slip sheets extend beyond just improved handling; they also contribute to space optimization within warehouses. By utilizing slip sheets, companies can increase storage density, as slip sheets take up significantly less space compared to pallets. This makes them an excellent choice for maximizing vertical space in warehouses. Additionally, the use of slip sheets reduces material costs, as they are often less expensive to produce and require less shelf space than traditional pallets.

By carefully selecting the right type of slip sheet, businesses can enhance their operational efficiency, streamline logistics processes, and ultimately improve their bottom line.

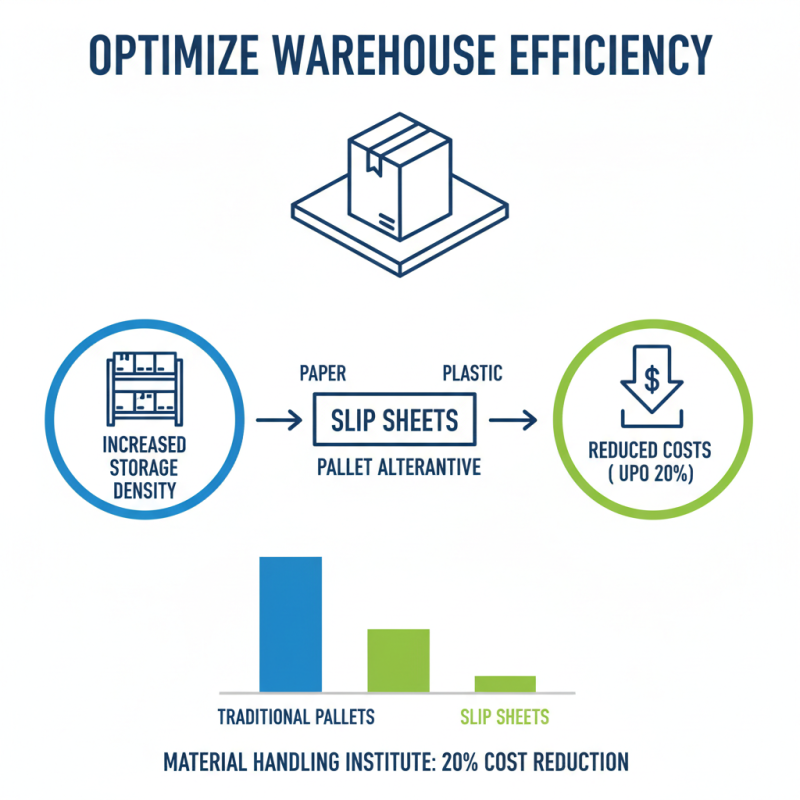

When evaluating material options for effective slip sheet solutions, it is crucial to consider the implications each material has on overall warehouse efficiency. Slip sheets, typically made from materials like paper or plastic, serve as a cost-effective alternative to traditional pallets. According to a report by the Material Handling Institute, optimizing materials in logistics can reduce costs by up to 20% and significantly increase storage density within warehouses.

Paper slip sheets are lightweight and recyclable, making them an environmentally friendly option that aligns with sustainable supply chain practices. They typically measure 48x40 inches and can effectively carry loads up to 1,500 pounds, providing a reliable solution for stacking and transporting goods. A study published by the International Journal of Logistics Management highlighted that paper slip sheets help companies save on transportation costs by enabling higher stacking configurations, thereby maximizing trailer space.

On the other hand, plastic slip sheets are durable and moisture-resistant, offering a longer lifespan, especially in environments with higher humidity or potential exposure to spills. They can withstand heavier loads, which is a significant benefit for industries dealing with bulkier products. A report from the Global Supply Chain Institute indicated that the adoption of plastic slip sheets has led to an average 15% reduction in packing materials used, further enhancing operational sustainability. By carefully considering these material options, warehouse managers can select the most suitable slip sheet solution to optimize efficiency and drive productivity in their operations.

Implementing slip sheets in warehouse environments can significantly enhance efficiency and reduce costs associated with traditional pallet systems. To ensure a successful transition, it is vital to follow best practices during the integration process. First, assess the compatibility of slip sheets with existing equipment, such as forklifts and pallet jacks, to avoid operational disruptions. Understanding the types of loads you will be handling is essential, as different materials may require specific slip sheet designs for optimal performance.

Tips: Ensure that staff is adequately trained in using slip sheets, as improper handling can lead to accidents and damage. Regular training sessions can help reinforce best practices and promote safe handling procedures.

Another critical aspect of implementing slip sheets is maintaining a clean and organized workspace. Slip sheets can be easily damaged by dirt or debris, so it's essential to establish a routine for cleaning and inspecting them. This practice not only prolongs the life of the slip sheets but also ensures that loads remain stable and secure during transport.

Tips: Utilize designated storage areas for slip sheets, making them easily accessible for operators. This can streamline your workflow and minimize time lost searching for equipment, ultimately contributing to a more efficient warehouse operation.

This chart illustrates the efficiency improvements observed in warehouses after implementing slip sheets. The data reflects various advantages measured across multiple dimensions, emphasizing the optimization potential of slip sheets in warehousing environments.

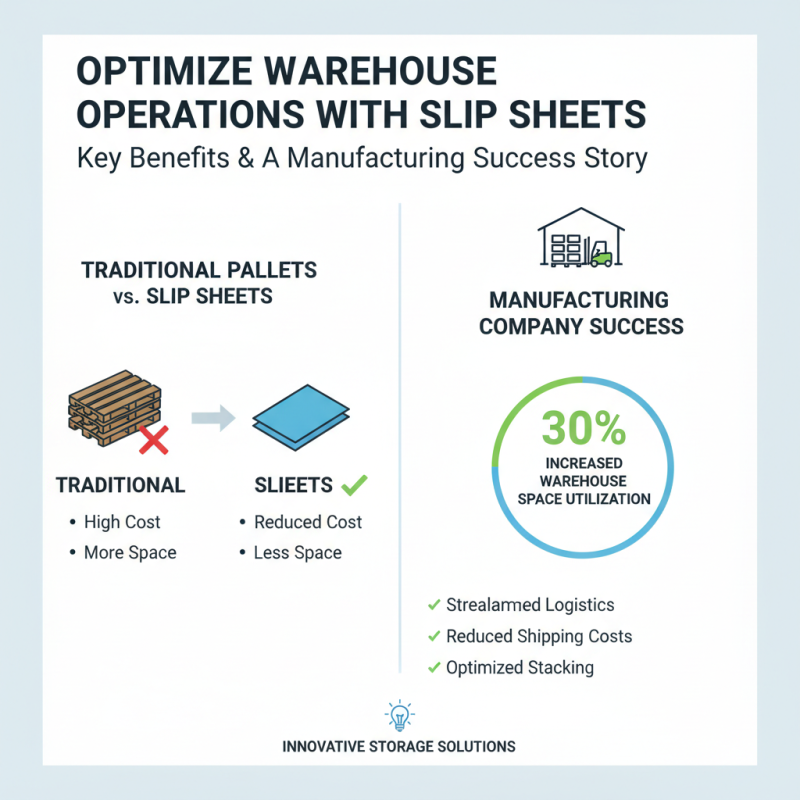

In various industries, businesses have successfully enhanced their warehouse operations through the innovative use of slip sheets. One notable case involved a manufacturing company that faced challenges with pallet costs and space limitations. The implementation of slip sheets allowed them to significantly reduce the footprint of their stored goods. By switching from traditional pallets to slip sheets, the company was able to optimize stacking and storage methods, leading to a 30% increase in warehouse space utilization. This adjustment not only streamlined their logistics process but also reduced shipping costs as fewer materials were needed for transport.

Another example comes from a food distribution center that struggled with the movement of perishable goods. After transitioning to slip sheets, the center improved their workflow dramatically. The lightweight nature of the slip sheets made it easier for their staff to handle products, and the ripple effect was seen in reduced physical strain and better safety outcomes. Enhanced efficiency meant that goods could be rotated faster, minimizing spoilage and ensuring fresher products reached the market swiftly. These case studies highlight how adopting slip sheets can lead to significant improvements in operational efficiency and cost savings for warehouses, emphasizing their value in modern inventory management strategies.