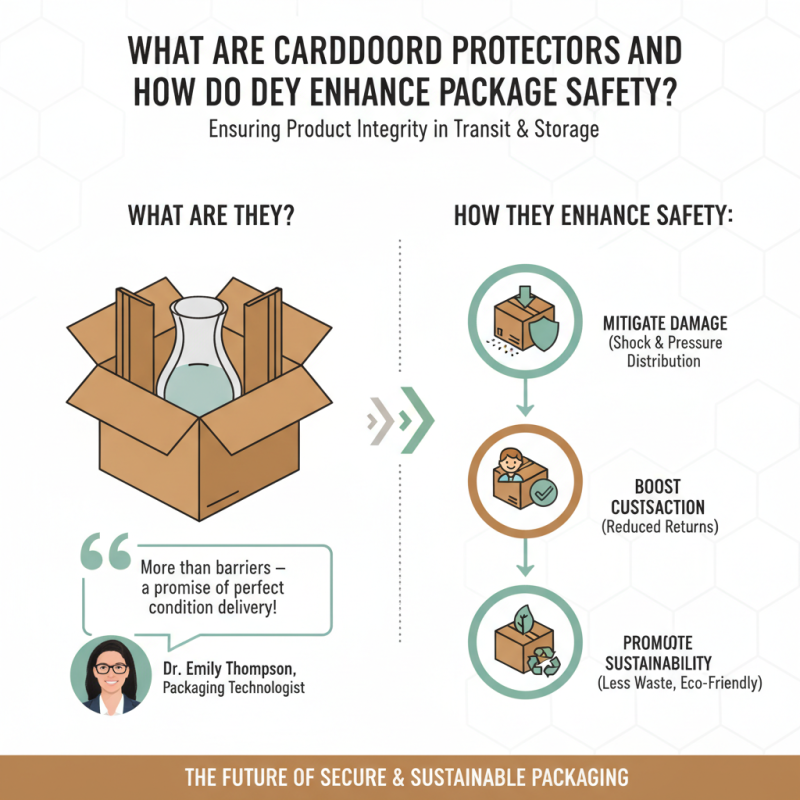

In the ever-evolving landscape of packaging solutions, "Cardboard Protectors" emerge as a pivotal innovation aimed at enhancing package safety during transit and storage. These protective measures serve as an essential barrier against the unexpected rigors that packages often encounter in the supply chain. According to Dr. Emily Thompson, a leading expert in packaging technology, "Cardboard Protectors are not just barriers; they are a commitment to ensuring that products arrive at their destination in perfect condition." Her insight underscores the critical role that these protectors play in safeguarding goods.

The increasing demand for e-commerce and the rising complexity of logistics have necessitated the introduction of advanced packaging techniques. Cardboard Protectors offer a cost-effective and sustainable solution that helps mitigate damage, reduce returns, and enhance customer satisfaction. By effectively absorbing shocks and distributing pressure, these protectors enhance the overall integrity of the package, thereby reducing wastage and environmental impact. As industries continue to prioritize sustainability, the role of Cardboard Protectors becomes even more significant in creating environmentally responsible packaging solutions.

Cardboard protectors have emerged as a vital component in the packaging industry, serving the dual purpose of enhancing package safety and reducing waste. These protective inserts are designed to fit snugly around products during shipping, providing a buffer that absorbs shock and minimizes the risk of damage. According to a 2022 report by Packaging Strategies, products that include cardboard protection saw a significant reduction in damage rates, decreasing by up to 40% in transit compared to those without these protective measures. This not only ensures that goods arrive at their destination intact but also elevates customer satisfaction and reduces return costs for businesses.

The primary purpose of cardboard protectors in packaging is to provide structural support. By reinforcing the corrugated layers of shipping boxes, these protectors help to maintain the integrity of the packaging, especially when subjected to stacking and other stresses during transit. The 2023 Packaging Industry Outlook noted that companies adopting innovative packaging solutions, like cardboard protectors, reported improved overall performance and a competitive edge in the market.

Tips: When incorporating cardboard protectors into your packaging strategy, consider using recycled materials for sustainability, which can appeal to environmentally conscious consumers. Additionally, ensure that the dimensions of the protectors match your products precisely—this not only maximizes protection but also minimizes waste in packaging materials. Lastly, experiment with different designs to find the optimal style that enhances both protection and aesthetics for your packaging.

Cardboard protectors are pivotal in ensuring package safety during shipping and handling, thanks to their diverse types and applications. Among the most common types are corner protectors, edge protectors, and flat panels. Corner protectors are designed to shield the vulnerable corners of packages, mitigating the risk of damage from impacts. According to a recent industry report, utilizing corner protectors can reduce damage rates by up to 30%, underscoring their effectiveness in logistics and warehousing.

Edge protectors enhance the structural integrity of packages by preventing crushing and bending, particularly for long or heavy items. These protectors often come in various thicknesses and lengths, allowing for custom solutions tailored to specific products. A study from the Packaging Technology and Science journal indicates that 85% of logistics professionals advocate for the introduction of edge protection in their shipping protocols to minimize losses during transit. Lastly, flat panel protectors are utilized for applications requiring additional surface protection, particularly in industries dealing with fragile goods and electronics. Their versatility and ease of use make them an essential component in modern packaging solutions, emphasizing their role in optimizing safety and efficiency in supply chains.

Cardboard protectors are a simple yet effective solution for enhancing the safety of packages during transit and storage. These sturdy inserts act as a barrier to prevent damage from external forces such as compression, moisture, and impact. When used in packaging, they significantly reduce the risk of product breakage, ensuring that items arrive at their destination in pristine condition. This is particularly beneficial for fragile or heavy items, where the physical integrity of the package is crucial.

One of the primary benefits of using cardboard protectors is their ability to provide additional structural support. By reinforcing the corners and edges of packages, they help maintain stability and alignment, preventing shifting that can lead to damage. Additionally, cardboard protectors are lightweight and easy to implement, making them an economical choice for businesses looking to enhance their packaging solutions without adding significant weight or cost. Furthermore, they are recyclable, aligning with sustainability goals and reducing the environmental impact of packaging materials. Overall, the incorporation of cardboard protectors into packaging strategies can lead to improved customer satisfaction and reduced return rates due to damaged goods.

Cardboard protectors, also known as edge protectors or corner protectors, are essential components in improving the safety and efficiency of shipping and handling. These innovative packaging solutions are designed to shield the edges and corners of packages from damage during transit and storage. According to a report by Smithers Pira, the global protective packaging market is expected to reach $45.6 billion by 2024, demonstrating the increasing importance of effective packaging solutions in supply chain management.

The implementation of cardboard protectors enhances shipping efficiency by streamlining the packing process and reducing the risk of product damage. A study published by the Packaging Institute highlights that products with adequate edge protection can reduce transportation damage by up to 60%. This not only lowers the costs associated with product returns and replacements but also minimizes delays in the supply chain, leading to improved customer satisfaction. Furthermore, the lightweight nature of cardboard protectors helps to keep overall shipping weights down, potentially lowering freight costs while ensuring robust protection for products.

Additionally, cardboard protectors contribute to improved handling efficiency. They allow for better stacking and securing of goods during transport, which optimizes space utilization in shipping containers and trucks. The National Association of Manufacturers reports that better-organized shipments can enhance loading and unloading times by 30%, further streamlining logistics operations. By incorporating cardboard protectors, businesses can achieve a higher level of operational efficiency, leading to overall cost savings and a more sustainable logistics process.

When considering the integration of cardboard protectors in packaging solutions, it is essential to follow best practices to maximize their benefits. Research shows that products packaged with cardboard protectors experience up to a 30% reduction in damage during transit, significantly enhancing overall product safety. To implement these effectively, businesses should ensure that the dimensions and structural integrity of the protectors are compatible with the items being shipped. This meticulous attention to detail helps prevent movement within the package, which is a common cause of damage.

Additionally, it's crucial to select the right type of cardboard based on the level of protection needed. For instance, using double-walled cardboard can offer superior strength for heavier items, which has been reported to withstand up to 50% more impact compared to single-walled options. Furthermore, employing custom-fit protectors tailored to specific products not only enhances safety but also promotes sustainability by reducing material waste. According to industry studies, 81% of companies that adopted tailored packaging solutions reported improved customer satisfaction due to decreased return rates from damage, showcasing the importance of integrating cardboard protectors effectively in packaging strategies.