In the ever-evolving world of logistics, ensuring the protection and stability of cargo during transportation is paramount. Dunnage bags have emerged as a vital tool for achieving this goal, offering versatile solutions to secure cargo and prevent damage. According to John Smith, a renowned expert in the dunnage bag industry, "Dunnagebags are essential for creating a stable platform that absorbs shocks and keeps goods safe, no matter the journey." With their ability to conform to the shape of the freight and fill voids in shipping containers, dunnage bags provide a cushioning effect that mitigates the risk of cargo shifting, ultimately enhancing the efficiency of the shipping process.

The use of dunnage bags is not just a matter of convenience; it is crucial for maintaining the integrity of products during transit. Properly inflated dunnage bags can withstand significant pressure, ensuring that cargo remains stable and protected against impacts that may occur on the road. This article will explore the best practices for utilizing dunnage bags effectively, including tips on optimal placement and inflation techniques. By leveraging the insights from industry experts and understanding the importance of these bags, shipping professionals can enhance their cargo protection strategies, leading to safer and more reliable deliveries.

Dunnage bags are integral to ensuring the safety and stability of cargo during transit. These inflatable bags are designed to fill void spaces in shipping containers or trailers, preventing movement and minimizing the risk of damage caused by shifting loads. By utilizing air to create a cushion between cargo items, dunnage bags offer a lightweight and efficient solution for maintaining the integrity of various shipments, from fragile goods to heavy machinery.

The benefits of using dunnage bags extend beyond mere protection. They provide an economical alternative to traditional packing materials, reducing shipping costs while enhancing cargo stability. Moreover, their ease of use allows for quick and effective loading and unloading, which can significantly streamline the shipping process. As they are reusable and recyclable, dunnage bags also contribute to more sustainable shipping practices, aligning with contemporary efforts towards environmental responsibility in logistics.

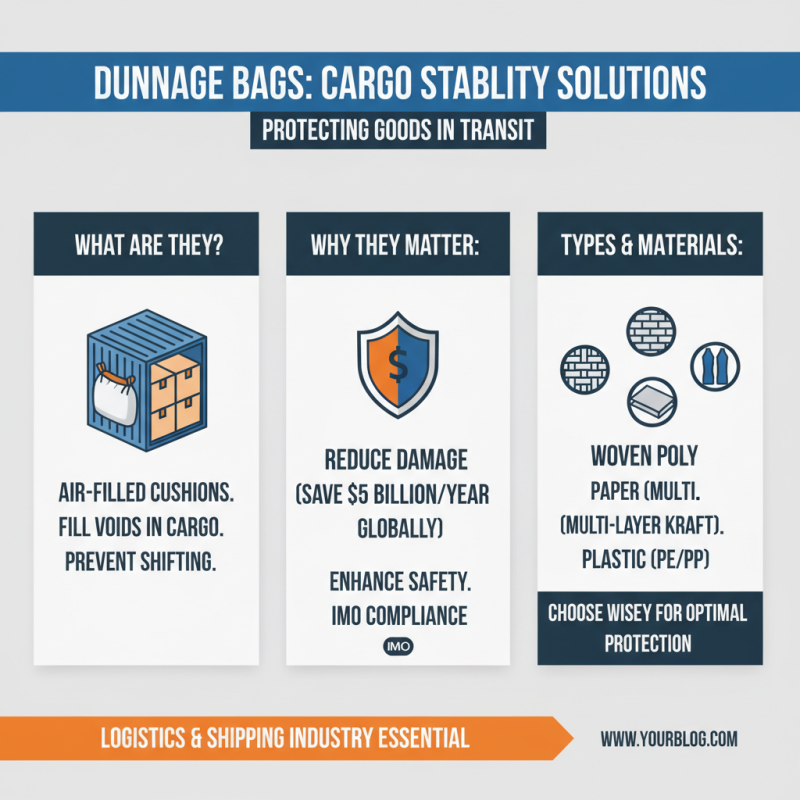

Dunnage bags have emerged as an essential tool in the logistics and shipping industries, providing effective cargo protection and stability during transport. These air-filled bags are designed to fill voids in cargo holds, preventing movement and reducing the risk of damage. According to the International Maritime Organization (IMO), improperly secured cargo can result in losses of up to $5 billion annually due to cargo shift incidents. Thus, the choice of dunnage bag types and materials is crucial for safeguarding goods during transit.

The key features of dunnage bags lie in their construction materials and types. Common materials used for dunnage bags include strong polyethylene and multi-layered combinations that offer enhanced durability and resistance to punctures. For instance, multi-layer bags can withstand high pressures and are often tested to endure weight loads of over 1,000 pounds per square inch. Different types, such as inflatable polyethylene dunnage bags or those reinforced with fiberglass, cater to various shipping requirements and material types. The effectiveness of these bags in maintaining cargo stability is further supported by data from the Council of Supply Chain Management Professionals (CSCMP), which highlights that the use of proper cargo securing methods can reduce freight damage claims by as much as 50%.

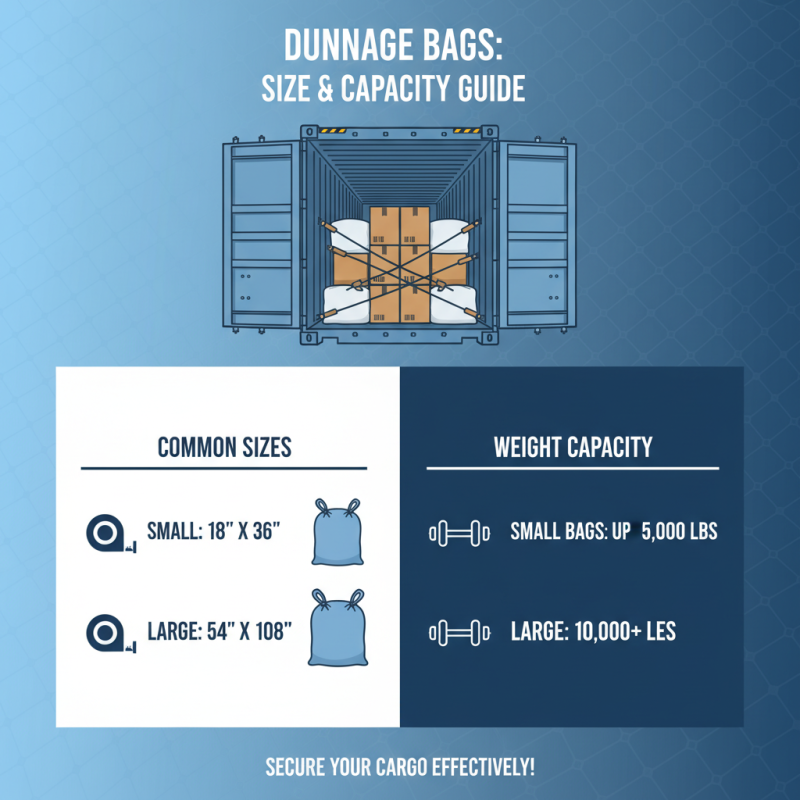

Dunnage bags play a crucial role in securing cargo during transportation, and understanding their dimensions and weight capacities is essential for effective usage. Typically, dunnage bags come in various sizes, ranging from small bags measuring approximately 18 inches by 36 inches to larger versions up to 54 inches by 108 inches. The size you select should correlate with the specific requirements of your cargo, ensuring adequate protection and stability. According to industry standards, the weight capacity of these bags often varies based on their dimensions; for instance, smaller bags can typically support loads of up to 5,000 pounds, while larger bags may handle capacities exceeding 10,000 pounds.

Moreover, adherence to industry standards, such as those established by the Institute of Packaging Professionals, is essential for cargo safety. Dunnage bags are designed to withstand significant pressures and forces during transport, with many capable of handling internal pressures exceeding 2 psi. When properly inflated and positioned, these bags not only cushion the cargo but also prevent shifting, which is crucial for maintaining equilibrium in transit. Proper utilization based on recognized standards ensures that cargo remains intact, ultimately reducing the risks of damage and loss for businesses operating in logistics and transportation sectors.

When utilizing dunnage bags for cargo protection, adhering to best practices during installation is critical for ensuring stability and minimizing damage. The first step involves selecting the appropriate bag size and type according to the cargo dimensions and cargo transport method. According to a report from the Dunnage Bag Association, improper sizing is a prevalent issue that can lead to cargo shifting, with studies indicating that around 15% of freight damage is caused by inadequate dunnage solutions. Once the right bags are selected, placement is essential; they should be inserted in voids and around the cargo to create a firm barrier that absorbs shock and prevents movement.

For effective installation, it’s important to prepare the area where the dunnage bags will be deployed. The surface should be clean to ensure that the bags can properly adhere to the cargo. Following this, inflate the bags using a compressed air source until they are taut, ensuring they fit snugly against the cargo's structure. A report from Logistics Management highlights that properly inflated dunnage bags can reduce the risk of damage by up to 60%, emphasizing the importance of achieving optimal pressure levels. Finally, secure the cargo as needed while ensuring that the dunnage remains intact, creating a stable load that can withstand the rigors of transportation.

Statistical analysis reveals the significant impact of dunnage bags on reducing cargo damage rates during transportation. In various studies, it has been observed that properly utilized dunnage bags can lower the incidence of damage by up to 40%. This reduction can be attributed to the bags’ ability to provide cushioning and stability, preventing cargo shifts and abrasions. The compression nature of dunnage bags absorbs impacts that would otherwise translate into damage to goods, such as crushed boxes or broken pallets, ultimately leading to better preservation of cargo integrity.

Moreover, the versatility of dunnage bags makes them effective across different modes of transport, including road, rail, and maritime shipping. Data collected from shipments using dunnage bags shows a consistent trend of fewer claims filed for cargo damage, highlighting their essential role in logistics management. By implementing dunnage solutions, companies not only safeguard their products but also enhance their overall operational efficiency. This proactive approach to cargo protection translates directly into financial savings, as lower damage rates can lead to reduced insurance costs and fewer delays in the supply chain process.