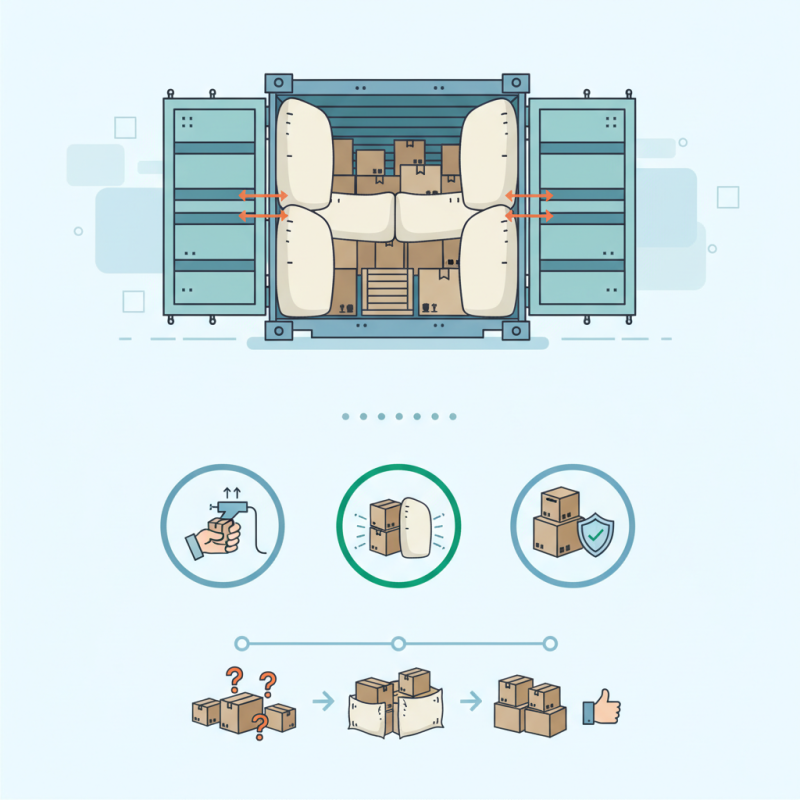

In today's shipping and logistics industry, effective packaging is crucial. One of the key tools for securing cargo is the Pp Woven Dunnage Bag. These bags play a significant role in preventing movement and damage during transit. When used properly, they can enhance stability and protect valuable products.

Understanding how to use a Pp Woven Dunnage Bag effectively can lead to better shipment outcomes. It is essential to know how to inflate and position these bags correctly. Improper use may result in cargo shifting, leading to potential damage. Take time to practice proper techniques and learn from any mistakes.

Visualize a scenario where cargo is in transit. A Pp Woven Dunnage Bag, tightly packed and properly inflated, acts as a barrier. It absorbs shocks and fills gaps. When used with care, these bags can prevent losses. Reflect on past experiences to improve your methods and ensure more successful shipments.

Pp woven dunnage bags are essential tools for secure cargo transport. They are made from durable, lightweight polypropylene. These bags can be inflated to create a protective barrier around your goods. This prevents shifting during transit. Using them can significantly reduce damage to fragile items.

One key benefit of pp woven dunnage bags is their versatility. They are suitable for various products, from glass to machinery. They fit snugly in different spaces, providing customized support. However, the correct inflation is crucial. Too much air can cause them to burst. Too little will not provide adequate protection. Finding the right balance takes practice.

The cost-effectiveness of these bags stands out. They are reusable and can lower shipping costs. Yet, some users forget to check for wear and tear. Neglecting this can lead to failure when you need them most. A proactive approach to inspection is essential for maximizing their lifespan.

When selecting PP woven dunnage bags, there are several key factors to keep in mind. The size of the bags is crucial. They should fit snugly into the spaces you want to fill. Measure the empty voids in your cargo. Proper sizing prevents shifting during transport. This reduces the risks of damage.

Another important aspect is the strength of the material. Ensure the bags are made from durable polypropylene. Stronger bags can hold up under pressure. Check for reinforced seams, as these contribute to overall durability. The bags should also be resistant to moisture. This feature protects against possible water damage during shipping.

Finally, consider the ease of use. Some dunnage bags are self-inflatable. These can save time during packing. Reflect on how often you'll be using them. Regular use might justify investing in higher-quality bags. On the other hand, occasional use could mean a more basic option suffices.

Always assess your specific needs before making a choice.

When it comes to inflating pp woven dunnage bags, accuracy is key. Start by selecting the right size for your cargo. Ensure the bag fits snugly in the load space. This prevents movement during transit. A bag that is too small may lead to inadequate support.

Before inflation, inspect the bag for any damage. Even small punctures can cause failures. Use a blower or pump designed for dunnage bags. Avoid using high-pressure systems that could pop the bag. As you inflate, monitor the shape; it should become evenly rounded. An improperly inflated bag may not provide the protection you need.

After inflation, check for stability. The dunnage bags should mold closely to the items they support. They must not be over-inflated, as this can lead to spontaneous bursts. If you notice any bulging or unevenness, adjust the inflation. It might take a few attempts to get it just right. Always keep an eye on the bags during transport.

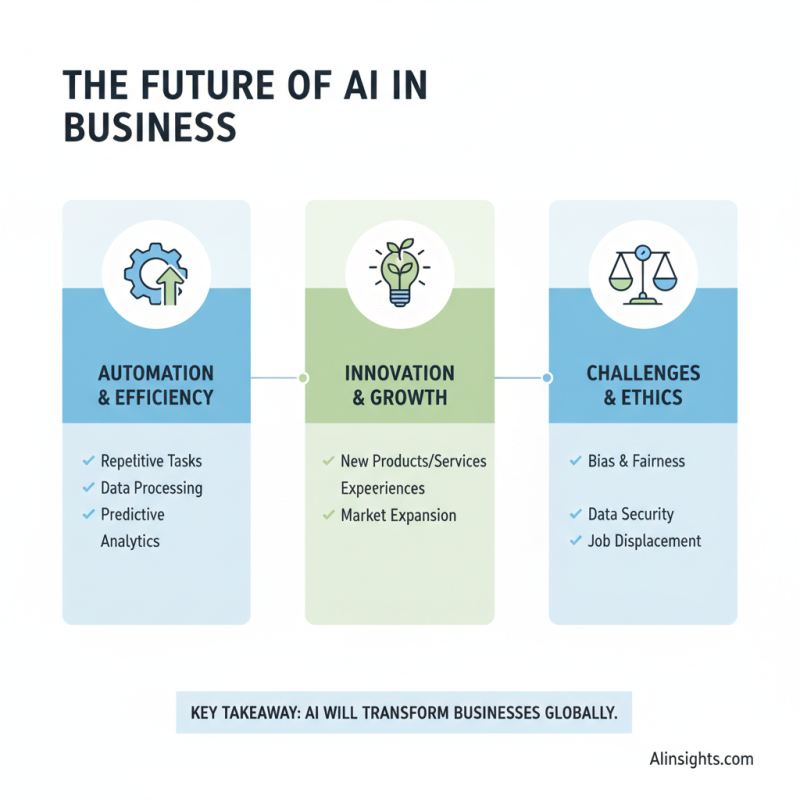

When securing Pp woven dunnage bags during transport, it’s crucial to follow best practices. Properly inflated dunnage bags can prevent cargo movement. Use just enough air to create stability, but avoid overinflation. Too much air can lead to damage during handling or transit.

Tips: Always check the bag for any punctures before use. A small hole can compromise the entire package. Use additional strapping or bracing to enhance stability. This method might seem basic, but it’s often overlooked amid busy operations.

Ensure the bags are positioned between loads. This spacing allows for optimal cushioning. However, be aware that poor placement can render them useless. Misaligned bags can lead to shifting during transport. Double-check each load's arrangement before sealing them for shipment.

| Best Practice | Description | Benefits | Recommended Applications |

|---|---|---|---|

| Proper Inflation | Ensure the dunnage bag is inflated to the correct pressure before sealing. | Prevents shifting of cargo during transport. | Heavy machinery and fragile goods. |

| Use Multiple Bags | Utilize multiple dunnage bags to secure larger loads. | Enhances stability and reduces risk of damage. | Bulk shipments and oversized items. |

| Correct Placement | Place dunnage bags at strategic points to fill voids. | Maximizes load security and minimizes movement. | Transportation of delicate items and mixed loads. |

| Seal Properly | Use appropriate seals to prevent air leakage. | Ensures bags maintain pressure throughout the journey. | Long-distance transport and overnight shipping. |

| Regular Inspections | Check condition of dunnage bags before and after use. | Identifies wear and tear, and prevents failure during transport. | Frequent shipping routes and repeated use. |

Proper maintenance and storage of PP woven dunnage bags can significantly extend their lifespan. A recent industry report suggests that improper handling can lead to a 20% reduction in durability. After use, ensure that the bags are cleaned thoroughly. Dust and debris can deteriorate the material over time. Avoid exposing the bags to extreme temperatures. Prolonged heat exposure may compromise the integrity of the woven fabric.

When storing dunnage bags, choose a cool, dry place. Humidity can encourage mold growth, which can cause irreversible damage. It's also essential to avoid stacking heavy objects on top of the bags during storage. This can lead to unnecessary pressure, leading to potential punctures. Periodically inspecting the bags for signs of wear or damage is crucial. A small tear can lead to larger failures if unnoticed.

Remaining aware of these maintenance steps can prevent costly replacements. A study indicated that businesses who neglect regular inspections incur up to 15% more expenses. Reflecting on these practices can lead to better management and efficient operations over time. Take the time to evaluate your storage techniques regularly. It's an investment in your product safety and efficiency.