In the transportation industry, ensuring the safety and security of cargo is paramount. One innovative solution to enhance load securement is the use of Load Securement Airbags. These airbags provide a cushioning effect that stabilizes loads during transit, mitigating the risk of shifting and potential damage. As industry expert John Smith, a renowned safety consultant, aptly stated, “Load Securement Airbags are revolutionizing the way we protect cargo, offering both safety and efficiency in transporting goods.”

The implementation of Load Securement Airbags not only contributes to the safety of the transported goods but also enhances overall road safety by reducing accidents caused by unsecured loads. With the growing emphasis on logistics efficiency, understanding how to effectively utilize these airbags has become crucial for transport operators looking to optimize their operations. This article aims to explore the best practices for using Load Securement Airbags, highlighting their benefits, proper installation techniques, and tips for maintenance to ensure maximum effectiveness in securing loads during transport.

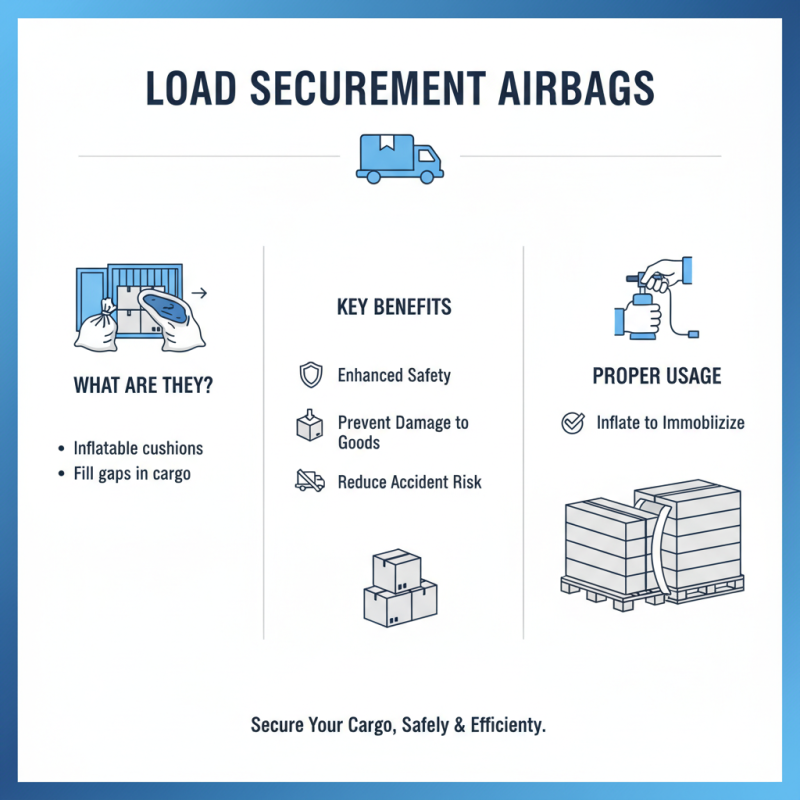

Load securement airbags are critical tools designed to enhance the safety of transporting goods. These airbags help stabilize loads during transit by filling gaps and preventing movement that could lead to shifting or tipping. Properly using load securement airbags ensures that the cargo remains immobile, safeguarding it from damage and reducing the risk of accidents caused by load movements.

When using load securement airbags, it's essential to follow best practices to maximize their effectiveness. **Tip 1:** Always assess the dimensions and weight of your cargo before selecting the appropriate airbags. This ensures that you use an adequate number of airbags to provide sufficient support. **Tip 2:** Position the airbags strategically between the cargo and the vehicle to create a balanced and secure setup, paying particular attention to uneven surfaces or gaps.

Understanding the importance of load securement airbags in transport cannot be overstated. They not only protect the cargo but also contribute to overall road safety. **Tip 3:** Regularly inspect the airbags for wear and tear, replacing any damaged units immediately to maintain their integrity during transport. By prioritizing the use of load securement airbags and adhering to these tips, transporters can significantly enhance the safety and reliability of their operations.

Load securement airbags are essential tools in ensuring the safe transport of goods, particularly in the trucking and logistics industries. These airbags come in various types, each tailored to meet specific applications based on the nature of the cargo being transported. For instance, among the most common types are inflatable airbags designed for heavy loads, which distribute weight evenly and prevent load shifting during transit. This is crucial for maintaining vehicle stability and ensuring cargo integrity.

In addition to heavy-load airbags, there are also specialized versions for delicate or fragile items. These airbags incorporate softer materials that allow for cushioning, reducing the risk of damage to sensitive goods such as electronics or glass. Furthermore, there are size-specific airbags that cater to varying load dimensions, providing versatility in cargo transport settings.

Their adaptability makes them a preferred solution for securing both uniform and irregularly shaped loads. By selecting the appropriate type of load securement airbags, transport operators can enhance safety and minimize the risk of accidents associated with shifting freight.

When installing load securement airbags, the goal is to ensure maximum safety and stability for transported goods. First and foremost, it's vital to assess the load's characteristics, including weight and dimensions, to determine the appropriate number of airbags needed for effective securement. Proper positioning is also crucial; airbags should be strategically placed to evenly distribute the load and minimize movement during transport. This helps to reduce the risk of shifting, which can lead to potential accidents.

Effective installation requires attention to detail and adherence to best practices. Begin by ensuring that the surface on which the airbags are installed is clean and free of debris, which can hinder adhesion and performance. Once in position, the airbags should be inflated according to the manufacturer's specified pressure levels. Over-inflation can lead to unexpected bursts, while under-inflation may not provide sufficient support.

Regular checks and maintenance of the airbags during travel are also essential to confirm they maintain the correct pressure and are not damaged. Following these guidelines will enhance the load securement process and contribute to safer transport outcomes.

When using load securement airbags, it's crucial to avoid common mistakes that can compromise safety during transport. One frequent error is overinflating the airbags. This can lead to unnecessary stress on the load and can cause the airbags to rupture, resulting in loss of securement. It's essential to follow the manufacturer's recommendations for inflation to maintain optimal performance and ensure a snug fit around the cargo.

Another mistake is inadequate placement of the airbags. Improper positioning can lead to ineffective load stabilization. Always ensure that airbags are placed in the correct locations to balance the load evenly and avoid shifting during transit. Using too few airbags for the size and weight of the load can also be detrimental. Assess the cargo dimensions and weight thoroughly to determine the appropriate number of airbags needed.

Tips for effective usage include regularly inspecting the airbags for wear and damage before and after each use. This vigilance helps ensure that any issues are addressed promptly, maintaining safety during transport. Additionally, consider practicing the loading process with empty airbags to familiarize yourself with the best placement strategies. This preparation can enhance overall efficiency and safety on the road.

| Mistake | Description | Consequences | Best Practice |

|---|---|---|---|

| Insufficient Inflation | Not inflating airbags to the recommended levels. | Reduced effectiveness in load stabilization. | Always follow manufacturer inflation guidelines. |

| Incorrect Placement | Placing airbags in improper locations. | Increased load shift and potential for accidents. | Refer to load diagrams for correct placement. |

| Neglecting Regular Inspection | Failing to regularly check and maintain airbags. | Risk of failure during transport. | Schedule routine inspections and maintenance. |

| Overloading | Exceeding the weight limits specified for airbags. | Increased likelihood of load failure. | Always adhere to weight limit regulations. |

| Ignoring Environmental Conditions | Not accounting for temperature or moisture issues. | Potential degradation of material properties. | Store and use airbags in appropriate conditions. |

The effective use of load securement airbags is crucial in meeting regulatory compliance and safety standards within the transportation industry. According to the Federal Motor Carrier Safety Administration (FMCSA), improper cargo securement is a common contributor to accidents, accounting for about 30% of all truck-related incidents. Load securement airbags play a vital role in enhancing the stability of loads during transit, helping to prevent shifts that can lead to dangerous situations on the road.

In order to remain compliant with safety standards, it is essential for transport companies to adopt load securement airbags that meet specific regulations outlined by governing bodies. For example, the National Highway Traffic Safety Administration (NHTSA) mandates that load securement devices must secure cargo to prevent movement, a requirement that load securement airbags can fulfill effectively.

Furthermore, recent studies highlight that vehicles fitted with quality load securement systems, including airbags, experienced a 25% reduction in cargo-related incidents. By investing in these safety measures, companies not only enhance their compliance with safety standards but also significantly improve overall transport safety.