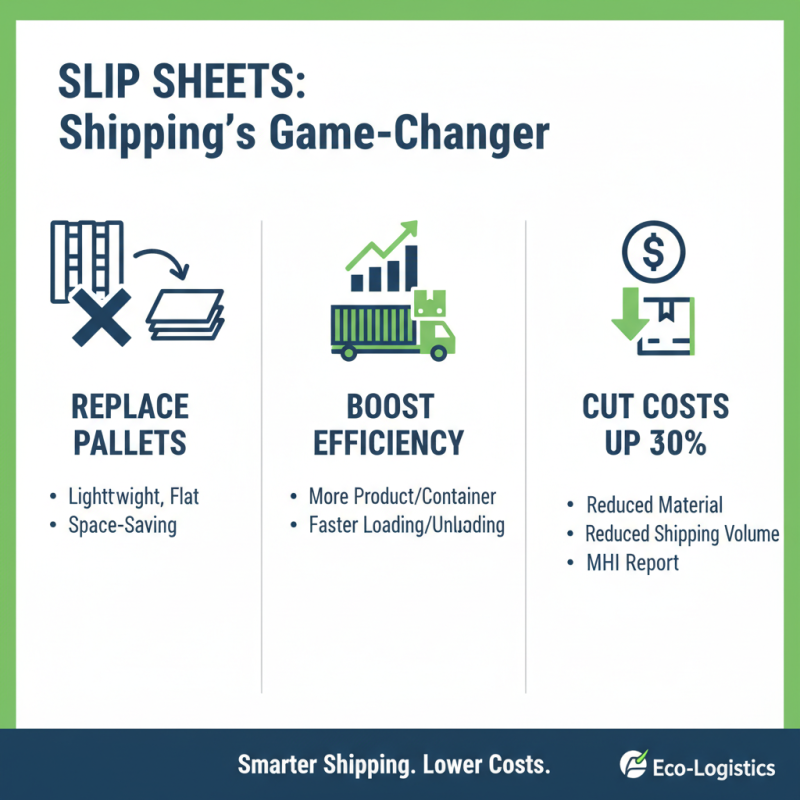

In the realm of logistics, the rising adoption of Slip Sheets is noteworthy. According to a recent industry report by Material Handling Industry, using Slip Sheets can reduce shipping costs by up to 30%. These thin sheets, typically made from plastic or paperboard, replace pallets and offer a more efficient way to secure goods for transport. Industry expert John Smith states, “Slip Sheets allow for better space utilization, reducing transportation costs significantly.”

However, despite their benefits, not all companies have embraced Slip Sheets. Some still cling to traditional pallets due to inertia or lack of understanding. This hesitation can cost them. Studies show that 70% of logistics professionals believe that utilizing Slip Sheets can lead to faster loading and unloading times. The shift to Slip Sheets also demands a reevaluation of handling equipment, which can be a daunting change.

The potential for improved shipping efficiency with Slip Sheets is immense. Yet, industry players must navigate the transition carefully. It's not just about adopting new technology; it’s about transforming mindsets. With the right implementation, Slip Sheets could reshape operational efficiency drastically.

Slip sheets are thin, flat sheets made from materials like plastic or cardboard. They serve as a base for palletizing goods. Manufacturers often use them to allow forklifts or pallet jacks to slide under them easily. This design reduces the need for traditional pallets, minimizing costs and material use.

Using slip sheets can enhance shipping efficiency. They occupy less space than standard pallets, which allows for more products in a single shipment. This compact design can lead to reduced freight costs and lower carbon emissions. However, slip sheets require trained personnel. Improper handling can lead to damaged goods or accidents.

Some challenges exist with slip sheet usage. For instance, not every type of product is compatible with them. Additionally, the transition from pallets to slip sheets may disrupt existing workflows. Companies need to assess their specific needs and consider training staff to maximize benefits. Adopting slip sheets isn't a one-size-fits-all solution; reflection on operational processes is crucial.

| Dimension | Description | Benefits |

|---|---|---|

| Material | Typically made from cardboard, plastic, or composite materials. | Durable and lightweight options reduce shipping costs. |

| Size | Standard sizes align with pallet dimensions (e.g., 48"x40"). | Maximizes space utilization in shipping containers. |

| Weight | Lightweight compared to traditional pallets. | Reduces overall shipping weight and costs. |

| Compatibility | Can be used with various shipping equipment like forklifts and hand trucks. | Enhances versatility in transportation methods. |

| Environmental Impact | Some slip sheets are recyclable or made from recycled materials. | Promotes sustainability in shipping practices. |

Slip sheets are a tool gaining traction in shipping. They are thin, flat sheets that facilitate the movement and storage of goods. By replacing traditional pallets, slip sheets offer several advantages that help improve shipping efficiency.

Using slip sheets can significantly reduce weight. This is crucial for companies aiming to cut transportation costs. Traditional pallets can be heavy and bulky. Slip sheets are lightweight and take up less space. This allows more products to fit within the same shipping container. Increased capacity leads to fewer trips and reduced fuel consumption.

**Tip:** Consider switching to slip sheets to optimize shipping. They save on both weight and space.

Additionally, slip sheets simplify the loading and unloading process. They can be used with specialized forklifts. This efficiency can cut labor costs. Traditional pallets require more handling, which can slow down operations. However, not all products are suitable for slip sheets. Fragile items may still need extra protection.

**Tip:** Test slip sheets with different products before making a full transition.

Embracing slip sheets may seem daunting. It requires adjustments in processes and equipment. Some companies have experienced challenges during the switch. However, the potential benefits can make a substantial difference in overall shipping performance.

Slip sheets are thin, flat sheets used in shipping. They offer an efficient alternative to pallets. With slip sheets, more items can fit into a shipping container. This maximizes space utilization significantly. In crowded containers, every inch matters.

Using slip sheets reduces weight and bulk. They don't take up much space themselves. This means you can load more products per shipment. Imagine fitting an extra layer of goods in a container. This could lower transportation costs. However, there are challenges. Not everyone is familiar with slip sheets. Some workers find them tricky to handle. Proper training is essential for effective use.

Also, slip sheets may not work for all products. Heavier or bulkier items may still require traditional pallets. Companies need to assess their own situations. Evaluating if slip sheets are right can save money, but the transition might be hard. Testing them in a small scale can be beneficial before full adoption.

Slip sheets are a game changer in the shipping industry. They are lightweight, flat sheets that replace pallets, significantly improving packing efficiency. According to a report by the Material Handling Industry, companies that switch to slip sheets can reduce their shipping costs by up to 30%. This is primarily because slip sheets take up less space, allowing more products to fit in a container.

The impact on efficiency is clear. With slip sheets, loading and unloading times can be cut by 50%. That’s valuable time saved in logistics. However, implementation can be tricky. Workers need training to use slip sheets effectively. If the crew is not well-prepared, the transition may lead to operational hiccups.

**Tip:** Invest in training your team on slip sheet handling. A well-informed team can maximize productivity.

Consider the potential downsides. Not all products fit well on slip sheets. Some items may still require traditional pallets for stability. Assess your inventory carefully before transitioning completely to slip sheets.

**Tip:** Conduct a trial with slip sheets on less critical shipments first. This allows you to gauge performance without risking major disruptions.

Implementing slip sheets in your supply chain can streamline operations. These thin, flat sheets act as a base for products, reducing the need for pallets. They can save space, cut costs, and enhance transportation efficiency. However, they require careful planning and training to use effectively.

Choosing the right size and material for slip sheets is crucial. A mismatch can lead to product damage or inefficiency. Employees need clear guidelines on handling slip sheets. Training programs should address potential challenges. Some workers may resist change, highlighting the need for support. Regular assessments can identify areas for improvement.

Slip sheets offer much promise, but they aren't a universal solution. Each operation has unique needs. Flexibility and adaptability are essential when introducing this method. Companies must remain open to feedback and adjust practices accordingly. Investing time in refinement can yield better results over time.