When it comes to securing goods during transportation and storage, Pallet Protection Corners play a crucial role in ensuring the integrity of products. These protective pieces are essential for mitigating the risk of damage by providing enhanced stability and cushioning, ultimately preserving the quality of your cargo. Utilizing Pallet Protection Corners effectively can lead to improved safety standards and increased efficiency in logistics, making it vital to understand their advantages and best practices.

In this guide, we will explore the key considerations for choosing the right Pallet Protection Corners tailored to your specific needs. From material selection to design features, understanding the different options available can significantly impact your shipping process. Furthermore, we will discuss practical tips on how to implement and use these protective corners effectively, ensuring that your pallets remain secure and your goods are well-protected throughout their journey. Whether you are a small business owner or part of a larger distribution network, mastering the use of Pallet Protection Corners can enhance your operational performance and reduce potential losses.

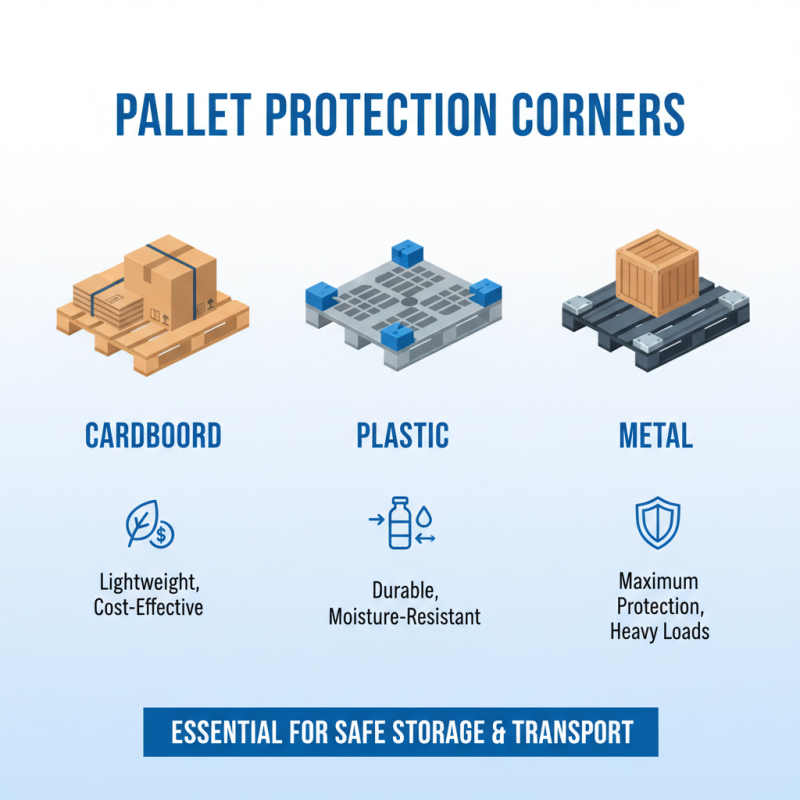

Pallet protection corners are essential components designed to safeguard both products and pallets during storage and transportation. They come in various types and materials, each serving distinct purposes. The most common types include cardboard, plastic, and metal corners. Cardboard corners are lightweight and cost-effective, making them an excellent choice for less heavy loads. Plastic corners offer superior durability and moisture resistance, ideal for industries where exposure to water is a concern. Metal corners, while more expensive, provide the highest level of protection, especially for heavy and fragile items.

When it comes to materials, the choice can significantly impact the efficacy of pallet protection corners. Cardboard, for example, is biodegradable and eco-friendly, appealing to companies with sustainability goals. However, it might not hold up well under extreme conditions. Plastic, on the other hand, is versatile and can be recycled, offering a good balance between strength and environmental considerations. Metal provides unmatched strength and is perfect for the heavy-duty sector, though its weight may add to shipping costs. Understanding these options allows businesses to select the most suitable pallet protection corners, ensuring optimal safety and integrity of their shipments.

Pallet protection corners are increasingly recognized as essential tools in the shipping and storage industries. These protective elements are designed to safeguard the edges of pallets during transit, significantly reducing the risk of damage to both goods and the pallets themselves. By providing a buffer against impact and abrasion, pallet protection corners help maintain the integrity of the products being transported, ensuring that they arrive at their destination in optimal condition. This not only reduces losses caused by damaged merchandise but also lowers replacement and repair costs.

Additionally, the use of pallet protection corners enhances storage efficiency. When pallets are stacked, these corners create a stable and secure interface between the layers, minimizing the likelihood of slippage or collapse. This added stability allows for better organization within storage facilities, maximizing space utilization and improving accessibility. Furthermore, with a reduction in product damage, the need for rework and returns is diminished, streamlining operations and improving overall supply chain efficiency. In essence, incorporating pallet protection corners into shipping and storage processes offers valuable benefits that contribute to a more reliable and cost-effective logistics solution.

| Dimension | Material | Benefits | Recommended Usage |

|---|---|---|---|

| 4 x 4 inches | Plastic | Durability, Lightweight, Water Resistant | Best for outdoor storage |

| 3 x 3 inches | Cardboard | Cost-effective, Recyclable | Ideal for lightweight products |

| 6 x 6 inches | Wood | Strong, Impact-resistant | Used for heavy loads |

| 5 x 5 inches | Metal | Maximum protection, Long-lasting | Recommended for industrial use |

| 4 x 4 inches | Foam | Shock absorption, Lightweight | Good for fragile items |

When selecting pallet protection corners, several key factors must be taken into account to ensure maximum safety and efficiency during transportation and storage. First and foremost, the material of the protection corners plays a vital role. Options such as plastic, cardboard, or metal provide varying degrees of durability and resistance to impact. Understanding the nature of the goods being transported will help determine which material can best withstand potential damage while maintaining the integrity of the pallet.

Another essential factor is the dimensions of the protection corners. It’s crucial to choose corners that fit snugly with the specific size of the pallets being used. Proper fit not only maximizes stability but also minimizes the risk of slippage during transit. Furthermore, it’s beneficial to consider the weight of the products being stored or transported. Heavier items may require reinforced corners to provide added strength and support, while lighter products may only need standard protection. By evaluating these considerations, businesses can enhance their packaging strategies and ensure their products are well safeguarded against potential hazards.

This chart presents an analysis of key factors to consider when choosing pallet protection corners, rated from 1 to 10 based on their importance. Durability is the most critical factor, followed by material quality and compatibility.

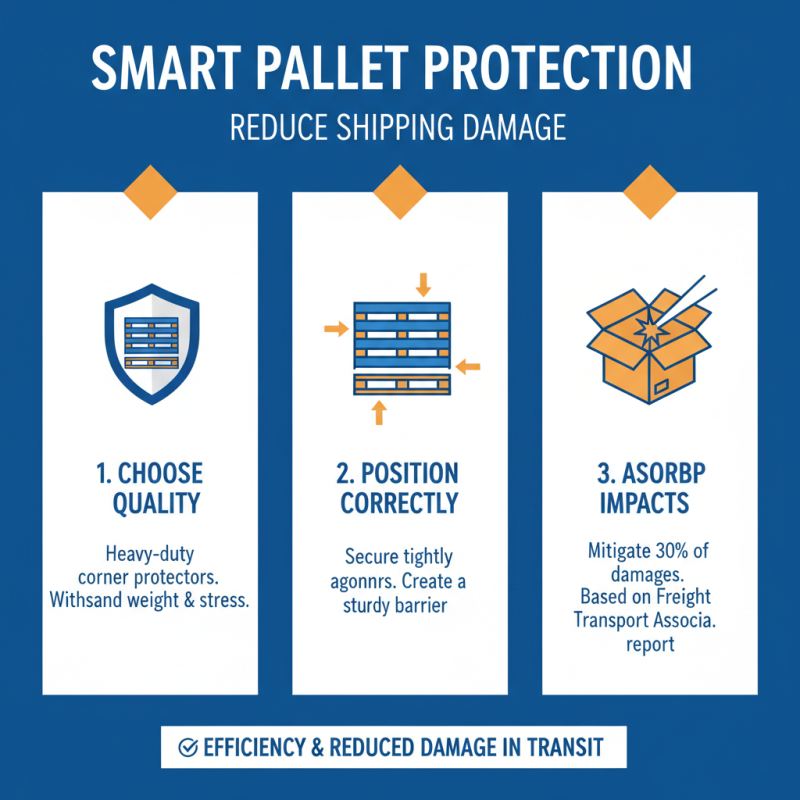

When it comes to the installation of pallet protection corners, a few best practices can significantly improve efficiency and reduce damage during transit. According to a report by the Freight Transport Association, approximately 30% of all shipping damages occur due to inadequate packaging practices. To combat this, ensuring that the corners are placed correctly is vital. Start by selecting heavy-duty corner protectors designed to withstand the weight and stress of stacked pallets. Proper positioning is crucial; they should be secured tightly against the corners of the pallets to create a sturdy barrier that absorbs impacts.

The installation process should also include comprehensive checks for alignment and stability. A study from the Packaging Innovation Group indicates that misaligned pallet corners can lead to an increase in material costs by up to 15% due to higher rates of product loss. Utilize strapping or stretch wrapping to reinforce the corners after installation, as this secures all items within the pallet, preventing shifting during transport. Training staff on these best practices can lead to a noticeable decrease in damage rates, ultimately enhancing operational efficiency and customer satisfaction.

Maintaining and replacing pallet protection corners is essential for maximizing their effectiveness and ensuring the longevity of your palletized goods. Regular inspections are crucial, as damaged corners can compromise not only the protection of the loads but also lead to increased shipping costs due to potential product damages. According to a recent industry report by Supply Chain Management Review, approximately 25% of products damaged during transport are attributed to inadequate protection. Thus, proactive management of pallet corners directly contributes to better supply chain efficiency and cost savings.

To ensure your pallet protection corners last longer, consider implementing a routine maintenance schedule. Inspect the corners for any signs of wear or damage after each use, and replace any that show significant signs of degradation. It is recommended to use corners made of durable materials, such as high-density polyethylene (HDPE), which can withstand the rigors of transportation and provide better protection than weaker alternatives. Regular replacement of worn corners helps in maintaining a high standard of safety for your products and the integrity of your overall logistics process.

Tip: Always keep a stock of spare pallet protection corners on hand to ensure quick replacements are possible, minimizing downtime during operations. Additionally, consider training staff on the proper ways to handle and store pallets with protection corners to further enhance their lifespan. Regular training helps prevent accidental damage and reinforces the importance of maintaining the condition of your pallet protection equipment.