In the rapidly evolving landscape of shipping and handling, Slip Sheets have emerged as a game-changer. According to a recent industry report, 40% of companies noted a significant decrease in shipping costs when integrating Slip Sheets into their logistics. They are lightweight and designed to replace traditional wooden pallets, leading to a 30% reduction in space during transport. These benefits highlight the efficiency of Slip Sheets in modern supply chains.

However, challenges still exist. The transition to Slip Sheets requires compatible handling equipment. Many companies hesitate, fearing potential disruption. Additionally, training staff on new handling protocols can be daunting. Nonetheless, the environmental impact of using Slip Sheets cannot be ignored. Their use contributes to reduced deforestation and waste. Packaging waste accounts for nearly 30% of landfill materials, making this innovation crucial for sustainability.

In light of the pressing need for efficient shipping solutions, understanding how to implement Slip Sheets effectively is vital. By addressing the barriers and optimizing existing processes, businesses can exploit the full potential of this innovative tool. Embracing Slip Sheets may require an initial investment in training and equipment; however, the long-term savings and environmental benefits are undeniable.

Slip sheets are thin, flat sheets made from materials like plastic or cardboard. They are designed to facilitate the movement of heavy loads. Unlike traditional pallets, slip sheets take up less space and are lightweight. This makes them ideal for shipping and handling solutions. Their compact size leads to savings on shipping costs. This is beneficial for businesses looking to optimize logistics.

Using slip sheets has several benefits. They reduce the weight of shipments, which can lower transportation costs. Additionally, slip sheets allow more items to fit in a shipping container. This efficiency can increase throughput. However, there's a learning curve when transitioning from pallets to slip sheets. Employees may need training to adapt to this new handling method.

Not all products are suitable for slip sheets. Fragile items may require a different approach. There can also be issues with compatibility in certain machinery. Companies should evaluate their needs carefully. It's a balancing act between efficiency and safeguarding products. The goal is to achieve streamlined operations without compromising on safety.

Slip sheets have become increasingly popular in modern shipping. They offer a cost-effective alternative to wooden pallets. According to a report by the Material Handling Industry, slip sheets can reduce shipping costs by up to 25%. This makes them appealing for many companies.

There are several types of slip sheets. The most common are made from cardboard, plastic, or composite materials. Cardboard slip sheets are lightweight and economical. They typically weigh about 5 pounds, making them easy to handle. Plastic slip sheets are more durable and resistant to moisture. They often last longer than their cardboard counterparts. Composite slip sheets, on the other hand, combine the best of both worlds. They offer strength while remaining lightweight.

Despite their benefits, slip sheets have drawbacks. Not all forklifts can handle them. Companies need to invest in specialized equipment. This can lead to unexpected costs. Some workers may also struggle with using slip sheets effectively. Training is essential to maximize their benefits. Industry reports suggest that up to 30% of companies face challenges in adopting this technology. Effective implementation requires careful planning and consideration.

Slip sheets are gaining popularity in warehouse operations for their efficiency and cost-effectiveness. These thin sheets act as a foundation for stacked goods, enabling efficient loading and transport. In fact, a 2022 industry report indicated that using slip sheets can reduce shipping costs by up to 20% compared to traditional pallets. This reduction is primarily due to the decreased space and weight requirements during transport.

Proper use of slip sheets involves training staff to adapt to new handling methods. It’s essential to ensure the right equipment is available, like forklifts designed for slip sheet use. Many warehouses struggle with this transition. Often, employees find it challenging to handle loads without the stability that pallets provide. A study by the Material Handling Institute noted that 32% of employees felt unsure about using slip sheets effectively. This reveals a gap in training that needs addressing. Organizations must invest time and resources into proper training to maximize the benefits of slip sheets.

Moreover, slip sheets may not fit every operation. For instance, some products require more control during transport. Fragile goods or varied shapes can complicate stack stability. This variability prompts a need for thoughtful consideration when integrating slip sheets into existing processes. Companies should regularly evaluate how well these solutions align with their operational demands. Continuous reflection can lead to better practices and improvements in efficiency.

Implementing slip sheets in your supply chain can lead to significant improvements. These thin sheets are lighter than pallets and save space. They allow for stacking loads more efficiently, which optimizes transportation. Proper training for staff is crucial. Ensure employees understand how to use slip sheets correctly. Mistakes in loading or unloading can lead to damage.

Consider the type of materials used for slip sheets. Different materials offer varying durability and weight-bearing capacities. Evaluate your needs carefully. Some industries might find that slip sheets are not suitable for all products. Reflect on your current processes. Are you fully aware of the areas where efficiencies can be gained? Observing real-time operations might uncover unexpected challenges.

Communication with your team is essential. Regular feedback sessions can help identify potential issues. It’s better to address concerns early. Also, get input from those on the front lines. They often have insights that management may overlook. Adopting slip sheets requires a shift in mindset. Be prepared for some trial and error as you integrate this solution into your workflow.

| Dimension | Description | Benefit |

|---|---|---|

| Weight | Typically around 3-5 pounds per sheet | Lighter than traditional pallets, reducing shipping costs |

| Size | Common sizes include 40"x48", 42"x42" | Standardized dimensions for easy handling |

| Material | Made from heavy-duty cardboard or plastic | Durable, allowing for multiple uses and reducing waste |

| Stackability | Designed for stacking with minimal slippage | Maximizes vertical space in shipping and storage |

| Compatibility | Can be used with forklifts, pallet jacks, and automated systems | Flexible integration into various supply chain processes |

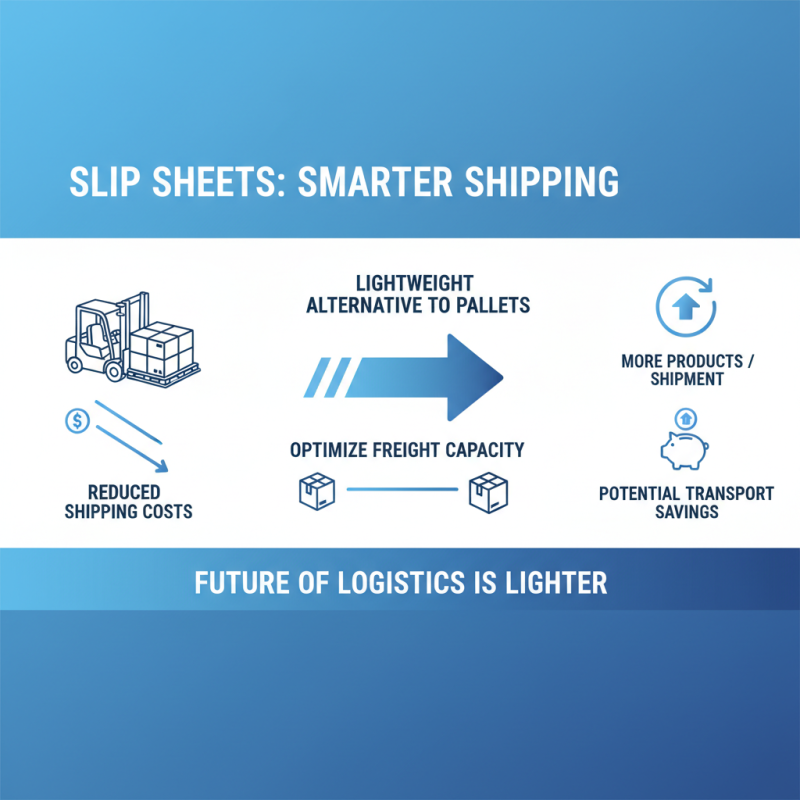

Slip sheets are becoming increasingly popular in shipping and handling. They offer a lightweight alternative to pallets, reducing overall shipping costs. By using slip sheets, businesses can optimize their freight capacity. This method allows for more products per shipment, potentially saving on transportation expenses.

When evaluating the cost savings, consider the storage aspect. Slip sheets require less space than pallets. However, transitioning to slip sheets may pose challenges. Employee training is essential to ensure proper handling. Workers may take time to adapt, leading to initial inefficiencies. The learning curve can affect productivity.

Moreover, not all products are ideal for slip sheets. Some items may require extra protection that slip sheets can’t provide. Reflecting on your needs is crucial. Assessing the impact on your operations can help you determine if the savings are worth it. Weigh the long-term benefits against the short-term hurdles before making a final decision.