01

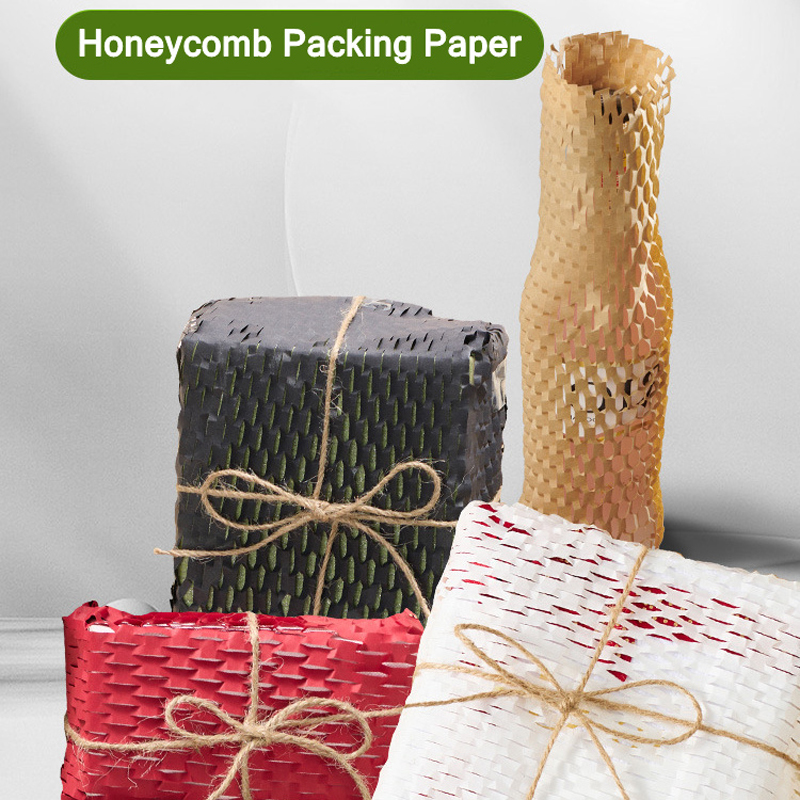

Honeycomb Packing Paper Kraft Cushion Paper

Characteristics of Honeycomb packing paper

1. Light weight, less materials and low cost

Compared with various other plate structures, the honeycomb sandwich structure has the largest strength/mass ratio, so its finished products have a good performance/price ratio, which is the key to the success of honeycomb paper.

2. High strength, smooth surface, not easy to deform

The honeycomb sandwich structure is approximately isotropic, has good structural stability, and is not easily deformed. Its outstanding compression resistance and bending resistance are the most important characteristics required for box packaging materials.

3. Good impact resistance and cushioning:

Honeycomb packing paper is made of flexible paper core and tissue. It has good toughness and resilience. The unique honeycomb sandwich structure provides excellent cushioning performance and has a higher energy absorption value per unit volume among all cushioning materials. , high-thickness honeycomb paper can replace the EPS plastic foam cushion that is widely used today.

4. Sound absorption and heat insulation:

The interior of the honeycomb sandwich structure is a closed chamber filled with air, so it has good sound insulation and thermal insulation properties.

5. No pollution, in line with modern environmental protection trends:

Honeycomb paper is entirely made of recyclable paper materials and can be 100% recycled and reused. Waste products and leftover materials from the corrugated box production process can also be die-cut and bonded to make honeycomb corrugated sheets of various shapes. Cardboard buffer lining can be degraded and absorbed by nature even if it is discarded. It is a good green and environmentally friendly packaging material.

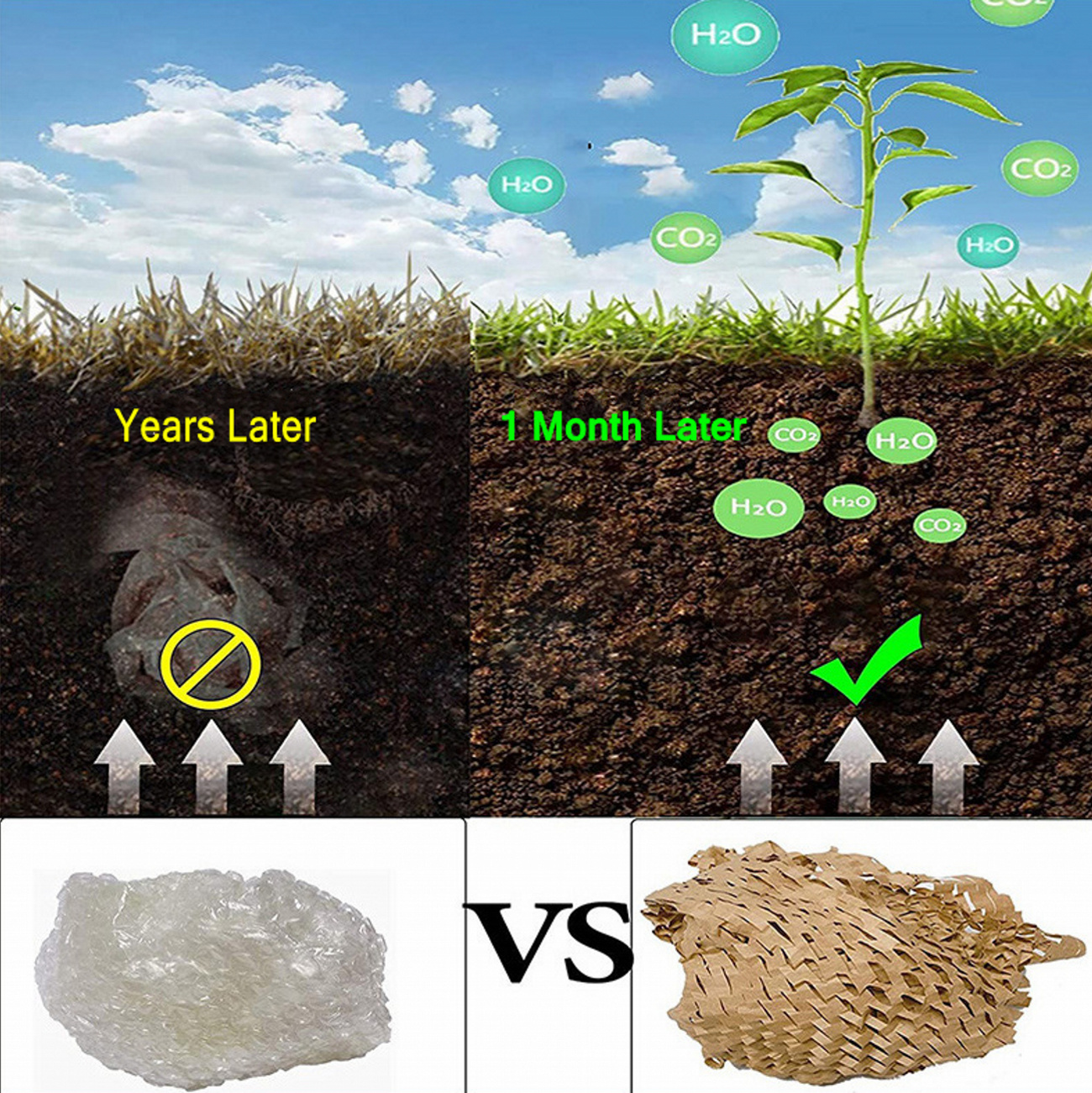

Why Choose Honeycomb Paper rather than Bubble Wrap?

Honeycomb packaging offers several benefits over bubble wrap, making it the superior packaging material:

1. Lightweight but strong:

Honeycomb packaging is lighter in weight than bubble wrap while still being strong. Thanks to its interlocking cells, honeycomb paper packaging grants greater strength and rigidity compared to other options. This ensures that it provides the ultimate level of protection to your product while still cutting down on shipping weight.

2. Cost-effective:

Honeycomb paper requires fewer materials than bubble wrap and other packaging solutions, making it cheaper to produce and purchase. Additionally, the reduction in shipping and handling fees, combined with reduced storage space, means that you also save on shipping costs when you use honeycomb packaging.

3. Eco-friendly:

Honeycomb paper is a sustainable alternative to plastic bubble wrap. It is 100% biodegradable and easy to be disposed. Besides, fewer trees will be cut down because it is made from recycled kraft paper.

4. Excellent flexibility:

Due to its expandable honeycomb structure and high tear resistance, honeycomb paper packaging is extremely elastic and malleable. This makes it great for wrapping around awkwardly shaped products, ensuring that they can be neatly placed in a well-protected package.

Honeycomb Paper Application

Honeycomb paper has a wide range of applications, such as stationery, cosmetics, handmade soap, wine, porcelain, glass products, lighting, picture frames, wooden boxes, fragile products, etc.