0102030405

Advantages and Disadvantages of Composite Strapping and PP Strapping

2025-07-28

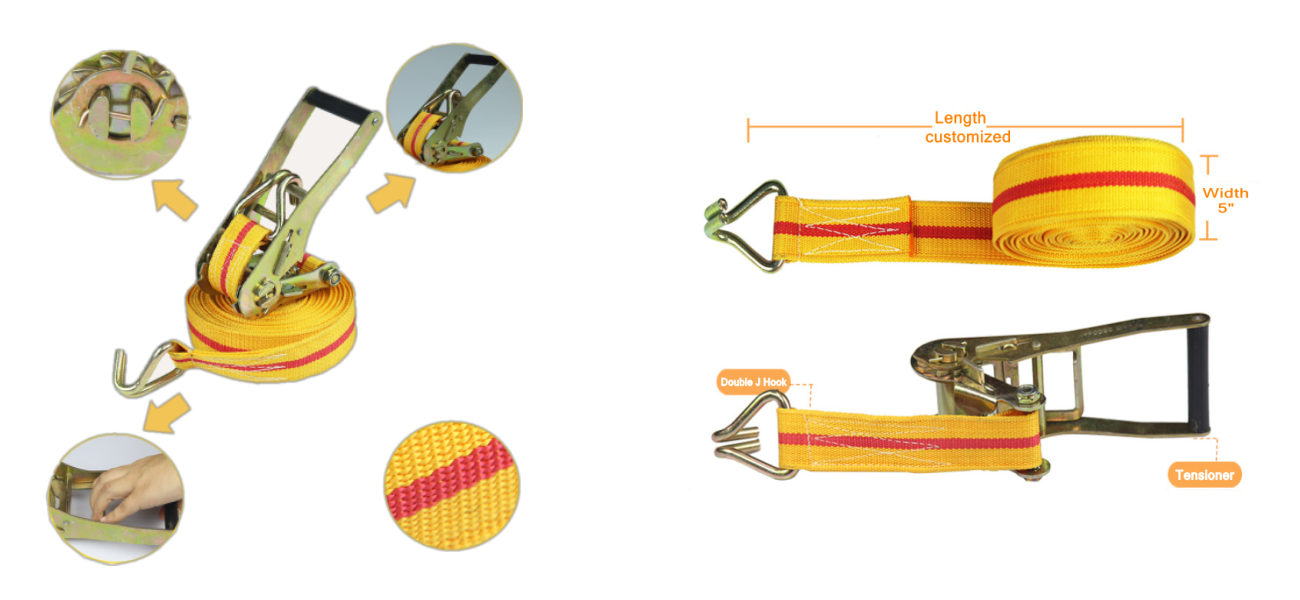

Flexible Composite Polyester Strap

Advantages

- High strength tensile strength: can withstand 0.5-8.5 tons of tensile strength, suitable for bundling heavy goods or pallets.

- High safety: The edges are soft and do not harm hands, nor will they scratch the surface of the packaging.

- Strong environmental adaptability: high temperature resistance (130 ℃), corrosion resistance, suitable for outdoor or humid environments.

Disadvantages

High cost: Raw material and processing costs are 30% -50% higher than Pp Strapping.

PP Strap

Advantages

- Lightweight material: Polypropylene material has low density and light weight, suitable for manual or semi-automatic packaging machine operation.

- Strong corrosion resistance: acid and alkali resistance, corrosion resistance, long service life.

- High cost-effectiveness: Low raw material costs, suitable for large-scale production.

Disadvantages

- Limited tensile strength: The maximum load-bearing capacity is usually between 0.5-2 tons, suitable for light to medium cargo.

- Strong rigidity: good elasticity and recovery, but with a hard texture, which may damage some goods (such as fragile items).

Selection suggestion:

If cost control and lightweight requirements are the main focus, PP strapping should be prioritized;

If higher load-bearing capacity or protection of the cargo surface is required, Aoli Pack composite polyester fiber strap is your best choice.

Aoli pack produce high quality Composite Polyester Strap, welcome your inquiry and visit.