How to evaluate the quality of paper corner protectors?

The main criteria for judging the quality of paper corner protectors include the following aspects:

1. Appearance quality: The surface of the Paper Corner Protector should be flat, smooth, and free of defects such as wrinkles, cracks, damage, stains, burrs, etc. The edges should be neat, straight, and free from missing, broken, or rough edges. For paper corner protectors with printed patterns or text, the printing should be clear, accurate, and firm, without blurring, smudging, fading, or other phenomena.

2. Dimensional deviation: The length, width, and thickness of the paper corner protector should meet the specified dimensional requirements, and the deviation should be within the allowable range. The angle detection index requires an external angle of 90 ° and a deviation within ± 5 °.

3. Physical performance:

Moisture content: The moisture content of paper corner protectors has a significant impact on their strength and performance. Generally, a moisture content of around 14% is required, with a deviation range of ± 4%.

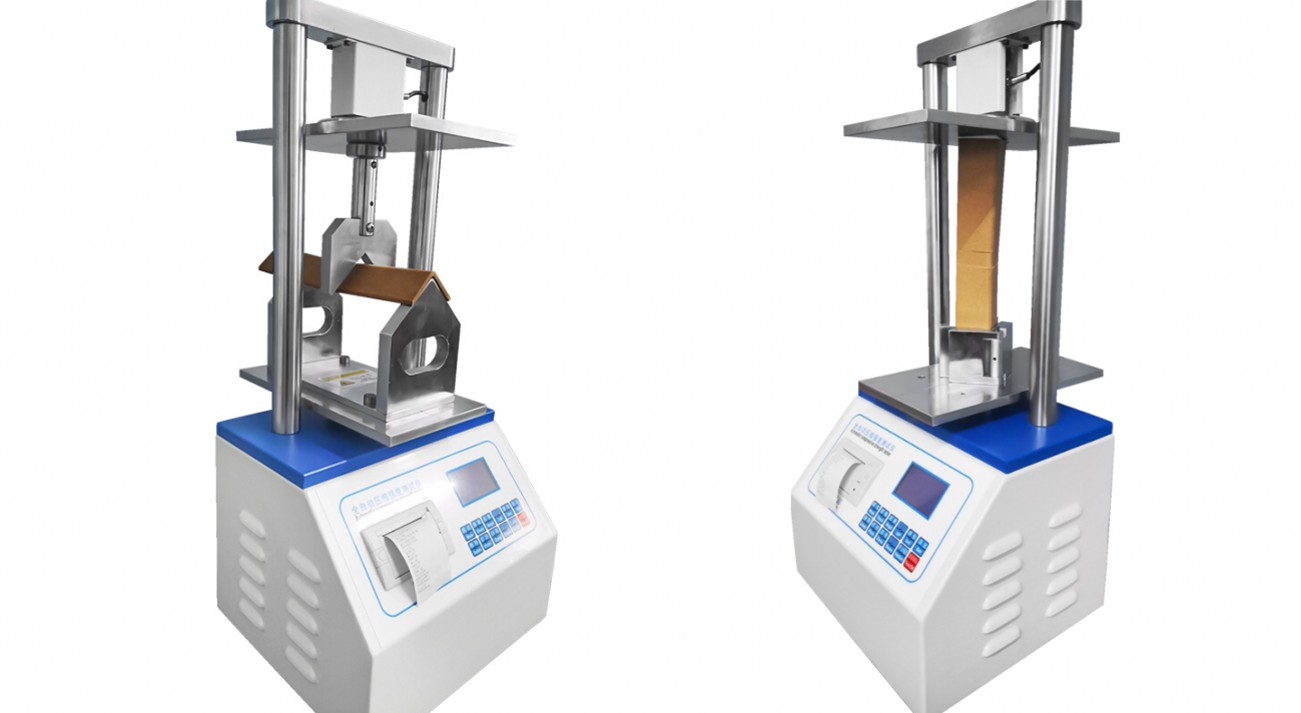

Compressive performance: The compressive strength of paper corner protectors is tested through longitudinal compressive tests, simulating the pressure they experience in actual use.

Bending resistance: Test the bending resistance of paper corner protectors to ensure that they are not easily broken when subjected to bending.

Adhesive strength: For multi-layer paper corner protectors, it is necessary to test the adhesive strength between each layer to ensure that there are no delamination, delamination, or other phenomena.

Durability: Evaluating the resistance of paper corner protectors to external impact.

4. Environmental adaptability: The stability of paper corner protectors under different climatic conditions is also important, and water resistance and weather resistance tests need to be conducted.

The specific detection methods of paper corner protectors include:

1. Appearance inspection: Inspect surface defects by naked eye or magnifying glass.

2. Dimensional measurement: Use calipers or measuring instruments to measure length, width, and thickness.

3. Moisture content detection: Measure by drying or other methods to ensure that the moisture content is within the specified range.

4. Compression and bending tests: conducted using a pressure testing machine and compression testing bracket.

5. Adhesive strength test: Check the adhesive strength between each layer through peel test.

6. Burst strength test: Use a burst strength testing machine for testing.

Through the above testing items and methods, the quality of paper corner protectors can be comprehensively evaluated to ensure their protective effect and durability during the packaging process. Regular inspection of paper corner protectors can help improve packaging quality, protect product safety, and is also an important means for enterprises to enhance product competitiveness.

Aoli Pack produces high-quality paper corner protectors, L corner protectors, and U-shaped corner protectors. Please feel free to inquire at any time.