What is the difference between honeycomb cardboard boxes and corrugated cardboard boxes?

1. Structural and physical differences:

The fundamental difference between honeycomb cardboard boxes and corrugated cardboard boxes lies in their internal core layer structure.

Honeycomb cardboard box: The core layer is a hexagonal honeycomb diamond structure, with a cardboard thickness range of 10-50 millimeters.

The box is made of honeycomb cardboard cut and combined with Paper Corner Protectors. The overall structure is similar to a wooden box and cannot be folded.

Corrugated cardboard box: The core layer has a wavy M-shaped structure, and the cardboard thickness is only 5-8 millimeters.

Made through die-cutting and indentation technology, it can be fully folded to save storage space.

2. Performance comparison:

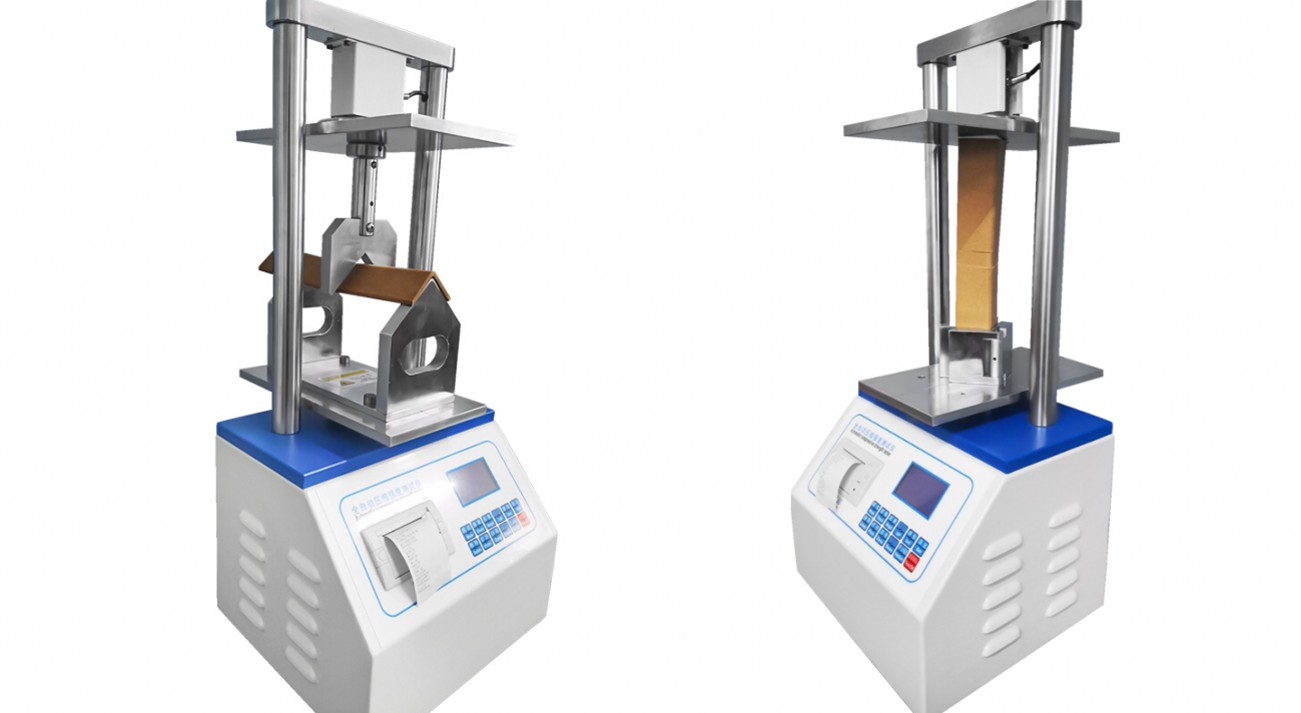

The mechanical properties of two types of cardboard boxes directly affect their application scenarios.

Load bearing capacity: The load-bearing strength of honeycomb cardboard boxes is 5-10 times that of corrugated cardboard boxes, and can support hundreds of kilograms of heavy objects (such as 600 kilograms of static pressure without deformation for three months), replacing wooden boxes.

The maximum load-bearing capacity of corrugated cardboard boxes is usually 50 kilograms, which is more suitable for lightweight goods.

Buffer and protection: Honeycomb cardboard boxes have excellent impact resistance due to their honeycomb structure that disperses stress. The breakage rate of fragile items is reduced by 50% -97% compared to corrugated cardboard boxes.

The cavity structure of corrugated cardboard boxes provides good shock absorption performance, but the puncture resistance strength is similar to that of honeycomb cardboard boxes.

Material efficiency: Honeycomb cardboard boxes save 60% of cardboard compared to corrugated cardboard boxes of the same specifications, with a weight ratio of approximately 2:5.

3. Application scenarios and applicability

Honeycomb cardboard boxes: heavy-duty cargo transportation (such as mechanical and electrical equipment, automotive parts), high-value fragile items (such as jade and handicrafts), and scenarios where wooden boxes need to be replaced. It has both packaging and cushioning functions, without the need for additional fillers.

Corrugated cardboard box: Lightweight packaging for daily consumer goods, electronic products, etc., with a folding design that facilitates storage and transportation. Lower cost, suitable for standardized mass production.

Aoli Pack is professional manufacturer of honeycomb cardboard, honeycomb cardboard pallet, honeycomb cardboard carton.

Welcome visiting us for deeper understanding of Aoli pack at any time!